Review Article

Quality Management Excellence in the Era of Industry 4.0 (Quality 4.0): A Comprehensive Review, Gap Analysis, and Strategic Framework

Abstract

Quality Management Excellence represents a continuous commitment to surpassing customer expectations through systematic improvement, standardization, and effective leadership. In the digital era, Quality 4.0 builds upon these foundations by integrating advanced Industry 4.0 technologies—such as artificial intelligence, the Internet of Things, cloud computing, and real-time analytics—into quality systems, fostering intelligent, agile, and data-driven decision-making. This study presents a comprehensive review of the Quality 4.0 paradigm, exploring its conceptual foundations, enabling technologies, practical applications, and implementation challenges. A gap analysis highlights key limitations in traditional quality practices, including fragmented digital infrastructures, underutilized data, limited adaptability, and inadequate human–machine collaboration. To address these challenges, a strategic Quality 4.0 framework is proposed, combining classical quality principles with digital tools and Lean Six Sigma methodologies to drive continuous improvement, enhance customer value, and optimize performance within interconnected environments. The framework defines strategic objectives and key performance indicators to support implementation, monitor progress, and enable continuous refinement, while also addressing critical enablers such as system integration, workforce development, data governance, and cybersecurity. Ultimately, the study positions Quality 4.0 as a transformative subset of Industry 4.0, shifting quality management from a reactive mindset to a proactive, predictive, and sustainable digital excellence, and outlines future research directions to support its sustainable advancement.

Keywords: Quality Management; Lean Six Sigma; Industry 4.0; Artificial Intelligence (AI); Quality 4.0; Smart Manufacturing; Autonomous Quality Control.

Introduction

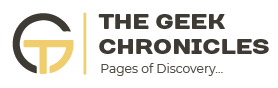

Excellence in Quality Management (QM) is increasingly defined by an organization’s ability to translate dynamic customer expectations into value-driven outcomes. As illustrated in Figure 1, this transformation is grounded in the integration of Voice of the Customer (VOC), Critical to Quality (CTQ), and Critical to Customer (CTC) constructs. These interconnected elements enable the systematic capture, interpretation, and deployment of customer needs into precise product and process specifications. When embedded within Lean Six Sigma (LSS) frameworks and empowered by Industry 4.0 (I4.0) technologies—such as Artificial Intelligence (AI), the Internet of Things (IoT), and Big Data Analytics—this triad establishes intelligent, adaptive, and customer-centric quality ecosystems. These ecosystems support real-time responsiveness, mass customization, and strategic alignment between operational excellence and stakeholder value. In contrast, traditional QM systems—characterized by manual inspections, fragmented feedback loops, and reactive decision-making—are no longer sufficient. They lack the agility, integration, and predictive capabilities needed to thrive in today’s increasingly complex and digital industrial environments (Dias et al., 2021; Ghobakhloo et al., 2021; Gomaa, 2024).

Figure 1. Critical To Quality (CTQ) Analysis.

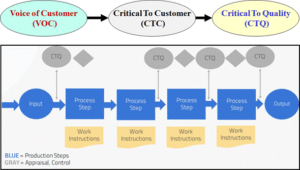

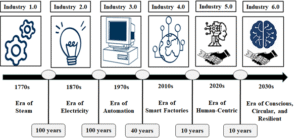

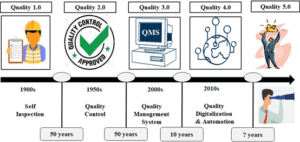

As shown in Figure 2, the evolution of industrial revolutions—from mechanization (Industry 1.0) to automation (Industry 3.0) and now to intelligent cyber-physical systems (Industry 4.0)—reflects a trajectory toward increasing complexity and integration. The emerging paradigms of Industry 5.0 and the conceptualization of Industry 6.0 signify a transformative shift toward human-centric, ethical, and regenerative industrial ecosystems. Figures 3 and 4 illustrate the parallel evolution of quality management, from inspection-based approaches (Quality 1.0) through statistical control and prevention (Quality 2.0) to strategic frameworks such as Total Quality Management (TQM) and business excellence (Quality 3.0), which emphasize stakeholder engagement and organizational learning. The advent of Quality 4.0 marks a pivotal shift—integrating digital technologies to create intelligent, self-regulating, and value-driven quality systems (Xu et al., 2018; Barata & Kayser, 2023; Gomaa, 2024).

Figure 2. Evolution from Industry 1.0 to Industry 6.0.

Figure 3. Evolution of Quality Management (QM).

Figure 4. Evolution of Quality Management.

The shift from Quality 3.0 to Quality 4.0 represents a transformation from values-based, process-oriented models to intelligent, interconnected, and data-driven ecosystems. While Quality 3.0 emphasized leadership, ethics, and stakeholder value, Quality 4.0 extends these foundations through cognitive automation, AI-enabled analytics, and agile governance structures. In this context, quality becomes a strategic enabler of foresight, innovation, and personalized customer experiences—demanding that quality professionals evolve into architects of intelligent and ethical systems. (Dias et al., 2021; Ghobakhloo et al., 2021; Gomaa, 2024).

Quality 4.0 reflects the strategic integration of advanced technologies—such as artificial intelligence (AI), the Internet of Things (IoT), blockchain, and cloud computing—to drive predictive quality control, real-time insights, and intelligent decision-making. Cybersecurity underpins this transformation, ensuring the integrity, reliability, and trust of interconnected systems. More than a technological upgrade, Quality 4.0 realigns quality management with digital transformation, innovation, and sustainability imperatives, positioning it as a proactive, ethical, and value-creating function. Implementation, however, is often hindered by legacy systems, cultural resistance, fragmented data, and talent shortages. Addressing these challenges demands a coordinated approach involving leadership commitment, digital maturity assessment, workforce upskilling, and cross-functional collaboration. Ultimately, Quality 4.0 marks a fundamental shift—redefining quality as a strategic enabler of intelligent, sustainable, and resilient performance in the digital age. (Weckenmann et al., 2015; Broday, 2022; Liu et al., 2023; Gomaa, 2024; Fundin et al., 2025).

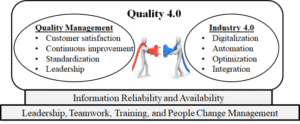

In conclusion, as illustrated in Figure 5, Quality 4.0 represents the digital transformation of quality management excellence through the strategic integration of core principles—such as customer focus, continuous improvement, standardization, and leadership—with advanced Industry 4.0 technologies, including AI, IoT, cloud computing, and real-time analytics. This convergence transforms quality into an intelligent, proactive, and data-driven function. It enhances process visibility, enables predictive and adaptive control, and delivers greater customer-centric value—while upholding the foundational pillars of quality. Ultimately, Quality 4.0 equips organizations with the agility, resilience, and innovation required to lead in an increasingly digital, dynamic, and competitive landscape.

Figure 5. Foundations of Quality 4.0.

This study investigates the shift to Quality 4.0, driven by the integration of Industry 4.0 technologies. It emphasizes the transition from reactive quality control to predictive, autonomous systems that support data-driven decision-making and continuous improvement. The study also addresses challenges, including integration complexity, change resistance, and workforce readiness, demonstrating how Quality 4.0 strengthens performance and competitiveness in the digital era.

The paper is structured as follows: Section 2 reviews the historical progression of quality management and Quality 4.0. Section 3 explores the challenges and barriers to Quality 4.0 adoption. Section 4 presents the proposed Quality 4.0 framework and its integration with Lean Six Sigma and digital technologies. Section 5 concludes the study and outlines future research directions.

Literature Review

This section examines the impact of Industry 4.0 on quality management, with a focus on the development of Quality 4.0, Kaizen 4.0, and LSS 4.0. A theoretical model is presented, integrating Industry 4.0 technologies—such as AI, IoT, big data, digital twins, and automation—with traditional quality management frameworks. This integration aims to optimize quality control, improve process efficiency, and enable agile, data-driven decision-making, shifting from reactive inspections to proactive, predictive systems. These advancements enhance product quality, operational performance, and competitiveness.

2.1 Review of Industry 4.0 Features and Technologies

This subsection focuses on the pivotal Industry 4.0 technologies and their transformative role in advancing manufacturing into intelligent, data-driven ecosystems. Introduced at the Hannover Fair in 2011 and formalized in 2013, Industry 4.0 marks a significant shift from traditional production methods to smart, automated systems powered by the integration of Cyber-Physical Systems (CPS), IoT, cloud computing, and big data analytics. These technologies enable continuous real-time monitoring, advanced predictive analytics, adaptive decision-making, and autonomous operations by seamlessly bridging physical and digital domains. This integration fosters the emergence of smart factories capable of managing complex, dynamic production processes with greater flexibility, efficiency, and sustainability (Hermann et al., 2016; Lu, 2017; Li, 2017).

Industry 4.0, or “smart manufacturing,” is rapidly gaining attention due to its potential to reshape business operations. Unlike traditional systems, it introduces more efficient methods for managing manufacturing processes, thereby improving product development, production, and delivery (Lasi et al., 2014; Ghobakhloo et al., 2021). By integrating advanced communication systems and intelligent technologies across manufacturing, operations, and supply chains, Industry 4.0 enhances efficiency (Tortorella & Fettermann, 2018; Fatorachian & Kazemi, 2018). The adoption of these technologies offers benefits such as improved knowledge sharing, greater productivity, reduced costs, better customer experiences, and enhanced innovation (Mohamed, 2018). Consequently, companies are increasingly adopting Industry 4.0 to strengthen competitive advantage and streamline operations (Sreenivasan & Suresh, 2024).

Industry 4.0 is transforming manufacturing, with developed countries leading the way (Narula et al., 2020). The global Industry 4.0 market, valued at $66.72 billion in 2016, is projected to grow to $227.29 billion by 2025, with a compound annual growth rate (CAGR) of 14.59% (Yacout, 2019). Countries worldwide are embracing Industry 4.0 to enhance manufacturing and boost global trade connectivity (Siau et al., 2019). In contrast, developing nations are still in the early stages of adoption, focusing on integrating these technologies into their systems (Kumar et al., 2021; Wang et al., 2017; Xu et al., 2018).

Industry 4.0 delivers significant economic, environmental, and social benefits. Economically, it improves planning, reduces lead times, and expands global reach. Environmentally, it optimizes resource use, minimizes waste, and enhances sustainability efforts. Socially, it advances workforce sophistication, reduces human dependency, and improves working conditions (Ghobakhloo, 2020; Sajdak & Młody, 2023). Sustainability remains a critical driver behind the adoption of Industry 4.0 (Ghobakhloo et al., 2021).

A key enabler of Industry 4.0 is the widespread adoption of Information and Communication Technologies (ICT), which underpin automation and real-time data collection. Technologies like machine-to-machine (M2M) communication, industrial data integration, and cloud-based systems optimize workflows and enable advanced applications such as digital twins, predictive maintenance, and real-time monitoring (Qin et al., 2016). These innovations drive operational efficiency by reducing waste and optimizing resource usage. Furthermore, Industry 4.0 fosters a shift towards adaptive, interconnected, and sustainable manufacturing ecosystems, making production systems more resilient in a dynamic market environment (Pereira & Romero, 2017).

Industry 4.0 has garnered global attention, with initiatives like Germany’s Industry 4.0 strategy and China’s Made-in-China 2025 plan leading efforts to modernize manufacturing through digital technologies (Xu et al., 2018). However, integrating these technologies with legacy systems remains challenging due to issues like data security, standardization, and interoperability, which hinder the full realization of Industry 4.0’s potential. Moreover, the rise of Industry 5.0 introduces a human-centric approach, focusing on balancing technological progress with societal values such as sustainability, ethical innovation, and worker well-being (Barata & Kayser, 2023).

Industry 4.0 has already made a significant impact on manufacturing areas such as supply chain management, lean production systems, and predictive maintenance. Witkowski (2017) explores how IoT and big data optimize supply chains by enabling real-time monitoring, data sharing, and adaptive decision-making. Mrugalska and Wyrwicka (2017) demonstrate how Industry 4.0 technologies improve lean production systems by identifying inefficiencies and optimizing manufacturing processes.

A transformative application of Industry 4.0 is predictive maintenance, which leverages real-time data and machine learning to monitor equipment health and predict failures before they occur. Kuo et al. (2017) developed a system that uses sensors and AI to detect defects in manufacturing processes, minimizing downtime and extending machinery lifecycles. This approach not only optimizes operations but also improves product quality by preventing unforeseen failures.

Industry 4.0 also introduces innovations like smart machines, smart factories, and augmented operators. Smart products autonomously communicate their status and production requirements to systems, while smart machines adapt to environmental changes and collaborate with other devices in an interconnected network. Augmented operators, equipped with technologies such as augmented reality, oversee production in real-time, ensuring optimal decision-making and production strategies. These innovations enhance flexibility, enabling product customization without compromising the efficiency of mass production (Mrugalska & Wyrwicka, 2017).

The disruptive potential of Industry 4.0 is driven by integrating real-time communication, automation, and data exchange across the value chain. Horizontal integration connects suppliers and customers, while vertical integration links business functions within organizations. End-to-end integration ensures seamless production and delivery processes (Zhou et al. 2016). Big data analytics plays a crucial role by processing large datasets and transforming them into actionable insights that guide optimization and decision-making (Witkowski, 2017).

Choudhary and Nandy (2024) explore the sustainability risks associated with Industry 4.0 adoption, identifying 16 sustainability risks and proposing a taxonomy that extends beyond the traditional triple bottom line to include organizational factors. Their research offers valuable insights for practitioners seeking to address sustainability risks in smart factories and contribute to the advancement of I4.0 sustainability research.

Barata and Kayser (2023) conducted a tertiary review of 32 literature reviews on Industry 5.0, supported by a bibliometric analysis of Scopus data. They define Industry 5.0 as a human-centric, sustainable evolution beyond Industry 4.0, identifying three research phases since 2018, with a recent focus on circular manufacturing and human-friendly digitalization that address societal and environmental challenges. Similarly, Rijwani et al. (2025) offer a comprehensive review on human-machine collaboration in manufacturing, examining key technologies such as Edge computing, IoT, Blockchain, AI, Cobots, Big Data, and 6G. Their study highlights these technologies’ roles in improving efficiency, discusses integration challenges, and outlines future research directions. Together, these studies provide valuable insights into the evolving landscape of Industry 5.0, emphasizing its transformative potential and the need for alignment with societal and environmental priorities.

In conclusion, Industry 4.0 is revolutionizing manufacturing through the integration of advanced technologies like AI, IoT, robotics, and big data, leading to improvements in operational efficiency, flexibility, and sustainability. Table 1 presents Key Technologies and Impacts of Industry 4.0 . These technologies enable the creation of smart factories and interconnected systems that optimize production, enhance quality control, and facilitate predictive maintenance. As Industry 4.0 evolves, it will continue to shape the future of manufacturing, fostering global competitiveness, sustainable growth, and resilient, data-driven manufacturing ecosystems (Črešnar et al., 2020; Barata & Kayser, 2023; Gomaa, 2024, Gomaa 2025 a-c).

- Connectivity and System Integration: Technologies such as the Internet of Things (IoT), Cyber-Physical Systems (CPS), cloud computing, and ERP systems enable real-time communication, system interoperability, and seamless data exchange across physical and digital domains. These tools support cross-functional collaboration, centralized data access, and remote operations—crucial for agile decision-making and enterprise-wide integration. Collaborative platforms further enhance knowledge sharing and distributed teamwork across digital workspaces.

- Real-Time Sensing and Monitoring: Smart sensors, sensor-based error detection, and AI-enabled monitoring systems empower organizations to capture real-time data for continuous performance assessment. These technologies enhance asset visibility, support early fault detection, and drive condition-based maintenance strategies. IoT-enabled tool tracking and telemetry extend these capabilities across the entire asset lifecycle.

- Automation and Process Control: Technologies such as advanced robotics, smart manufacturing cells, automated conveyor systems, and workflow automation software drive precision, consistency, and speed in manufacturing and logistics. Automated inspection systems and inventory management tools ensure quality and accuracy in repetitive operations, while reducing manual intervention and cost. These systems support high-mix, low-volume production and operational flexibility.

- Digital Modeling and Simulation: Digital twins, VR/AR systems, simulation tools, and process mapping software facilitate virtual experimentation, real-time optimization, and risk analysis. These tools improve planning, support remote training, and enable predictive maintenance by visualizing future scenarios and system behavior.

- Analytics and Intelligent Decision Support: Technologies such as machine learning, big data analytics, predictive maintenance platforms, and decision support systems provide data-driven insights for proactive operations and strategic planning. These systems unlock hidden patterns, optimize resource use, and support real-time problem-solving and long-term forecasting.

- Visualization and Alerting: Augmented reality (AR), digital Kanban boards, and real-time alert systems enhance situational awareness and operator responsiveness. These technologies visualize workflows, guide decision-makers, and ensure timely intervention in case of anomalies or deviations.

- Cybersecurity and Data Integrity: To ensure trust and resilience in digital operations, cybersecurity frameworks safeguard industrial networks, data, and infrastructure from cyber threats. Blockchain technology enhances transparency, traceability, and immutability, particularly in supply chain and compliance-related applications.

In essence, these technologies serve as the foundation of Quality 4.0, enabling intelligent quality management systems that are proactive, adaptive, and data-driven. Their strategic integration enhances operational agility, predictive capability, and continuous improvement—essential pillars for achieving excellence in the era of digital manufacturing.

Table 1. Key Industry 4.0 Technologies and Their Strategic Impact

| Category | Technology | Strategic Purpose | Key Applications |

|---|---|---|---|

| Connectivity & Integration | Internet of Things (IoT) | Real-time connectivity and data exchange | Asset tracking, remote condition monitoring |

| Cyber-Physical Systems (CPS) | Integrate physical and digital systems | Real-time control, system coordination | |

| Cloud Computing | Scalable data storage and remote access | Cloud-based platforms, application hosting | |

| ERP Systems | Enterprise-wide integration of core processes | Finance, operations, supply chain | |

| Collaborative Platforms | Digital collaboration and information sharing | Remote work, cross-functional coordination | |

| Sensing & Monitoring | Smart Sensors | Real-time data capture and transmission | Equipment health, process monitoring |

| Sensor-Based Error Detection | Automated defect detection | Quality assurance, downtime prevention | |

| AI-Powered Monitoring | Predictive and prescriptive insights | Performance optimization, anomaly detection | |

| IoT-Enabled Tool Tracking | Asset visibility and loss prevention | Tool utilization, inventory accuracy | |

| Automation & Control | Advanced Robotics | Precision automation and repetitive task execution | Assembly, material handling |

| Smart Manufacturing Cells | Flexible and modular production | Agile manufacturing, mass customization | |

| Smart Conveyor Systems | Intelligent material flow | Logistics, throughput optimization | |

| Workflow Automation Software | Process digitization and efficiency | Task execution, approvals | |

| Automated Inventory Systems | Real-time inventory control | Replenishment, warehouse optimization | |

| Automated Inspection Systems | Quality control automation | Defect detection, compliance verification | |

| Modeling & Simulation | Digital Twin | Virtual representation of physical systems | Predictive maintenance, performance optimization |

| Virtual Reality (VR) | Immersive design and training environments | Safety training, design validation | |

| Simulation & Modeling Tools | Scenario analysis and risk mitigation | Capacity planning, system optimization | |

| Process Mapping Software | Workflow visualization and process improvement | Lean initiatives, bottleneck analysis | |

| Analytics & Intelligence | Machine Learning (ML) | Data-driven learning and optimization | Predictive maintenance, quality prediction |

| Big Data Analytics | Insight extraction from complex datasets | Trend analysis, strategic planning | |

| Predictive Maintenance Tools | Early failure detection | Downtime reduction, lifecycle extension | |

| Decision Support Systems | Informed decision-making | Resource planning, operational strategy | |

| Visualization & Alerting | Augmented Reality (AR) | Contextual digital overlays for task support | Maintenance assistance, operational guidance |

| Digital Kanban Boards | Visual workflow management | Task tracking, process flow visualization | |

| Real-Time Alert Systems | Immediate issue notification | Incident response, downtime mitigation | |

| Security & Trust | Cybersecurity | Protection against cyber threats | Data integrity, system resilience |

| Blockchain | Decentralized, secure recordkeeping | Supply chain traceability, data authentication |

2.2. Review of Quality 4.0

Quality Management (QM) has traditionally focused on customer orientation, continuous improvement, process control, employee involvement, and data-driven decision-making. The advent of Industry 4.0 technologies—including Artificial Intelligence, the Internet of Things, Machine Learning, Big Data Analytics, Digital Twins, Blockchain, and Cyber-Physical Systems—has propelled these principles into Quality 4.0. This evolution shifts quality management from reactive, manual approaches to intelligent, autonomous systems capable of real-time decision-making, early defect detection, process optimization, and continuous improvement. As a result, Quality 4.0 significantly enhances efficiency, precision, and agility, enabling superior quality outcomes in today’s smart manufacturing and service landscapes (Liu et al., 2023; Gomaa, 2025a-c).

Quality 4.0 is more than just an upgrade to traditional TQM principles; it represents a paradigm shift in the approach to quality management. Through Industry 4.0 technologies, Quality 4.0 enables organizations to transition from reactive to proactive, data-driven systems that anticipate potential issues and adjust operations in real time. This shift enhances resilience, agility, and sustainability, particularly in complex, tech-driven environments (Nguyen et al., 2023; Broday, 2022). The fusion of human expertise with advanced technology also improves organizational transparency, fosters innovation, and accelerates continuous improvement.

Dias et al. (2022) conducted a bibliometric analysis to explore the evolving concept of Quality 4.0. Their study found growing academic interest in the field, with an emphasis on technological dimensions. However, they also highlighted the increasing recognition of business strategy, management systems, and human factors in the successful implementation of Quality 4.0. Their work offers a synthesized definition of Quality 4.0, which clarifies the concept and guides future research.

Maganga and Taifa (2022) explored the rise of Quality 4.0, highlighting its connection to digitalization and big data, as well as the convergence of operational and information technologies. The study identified key enablers for adopting Quality 4.0, such as technological capabilities, data proficiency, skilled talent, leadership, and collaboration. These insights provide a foundation for the successful implementation of Quality 4.0 in modern quality management practices.

Sureshchandar (2023) developed and validated a comprehensive measurement model for Quality 4.0, identifying 12 foundational axes essential for its implementation. The study confirms that while digital technologies are vital for Quality 4.0, traditional quality management principles remain essential for a smooth transition. This research provides a practical framework for both scholars and practitioners, setting the stage for further exploration in the field.

Thekkoote (2022) conducted a literature review and identified ten critical success factors for implementing Quality 4.0. These factors include data, analytics, connectivity, collaboration, app development, scalability, compliance, organizational culture, leadership, and training. These elements provide a structured approach for organizations seeking to improve their quality systems through digital transformation.

Zonnenshain and Kenett (2020) addressed the stagnation of traditional quality management models and proposed Quality 4.0 as a revitalizing framework. They explored key aspects such as data-driven quality management, evidence-based quality engineering, health monitoring, and the integration of innovation with quality. While the framework is not exhaustive, it offers a valuable starting point for updating quality management practices in the digital era.

Quality 4.0 integrates two key dimensions: soft and hard. The soft dimensions, including leadership commitment, human resource management, customer focus, and employee development, are crucial for fostering a culture of quality, agility, and innovation. These dimensions empower employees, promote collaboration, and support organizational growth (Ali & Johl, 2023b). In contrast, the hard dimensions focus on technological infrastructure and systems that enable the digital transformation of quality management. These include process management (PM) using IoT and CPS for real-time optimization, and quality information analysis (QIA) leveraging big data and advanced analytics (Ali et al., 2022). By harmonizing these soft and hard dimensions, organizations can achieve operational excellence and align with Industry 4.0 objectives.

Key technologies in Quality 4.0, such as predictive maintenance and digital twins, facilitate a proactive approach to quality management. Predictive maintenance tools use real-time sensor data to anticipate equipment failures and minimize downtime, while digital twins enable the simulation of processes for optimization before making real-world adjustments (Albers et al., 2016). These innovations help organizations improve process quality, detect issues early, and boost operational efficiency.

The integration of real-time customer feedback is another hallmark of Quality 4.0. By incorporating customer data into the production cycle, organizations can quickly adapt to customer needs, customize products, and improve satisfaction. Automated quality control systems further enhance manufacturing efficiency by identifying and correcting defects early in the process (Sader et al., 2019). Real-time feedback also accelerates product iterations, enabling manufacturers to deliver more personalized and responsive solutions.

Babatunde (2021) explored the competencies necessary for implementing Industry 4.0 within TQM, revealing key insights from a study of early-career engineering professionals. The study emphasized the importance of balancing hard and soft TQM competencies to ensure successful Quality 4.0 adoption.

For Small and Medium-sized Enterprises (SMEs), the adoption of Quality 4.0 poses challenges due to resource constraints, limited digital expertise, and technological immaturity. However, by aligning soft dimensions like leadership and employee engagement with hard dimensions such as data analysis and process management, SMEs can overcome these challenges and enhance their operational performance, quality management, and customer satisfaction (Santos et al., 2021). Success in Quality 4.0 lies in fostering a culture that embraces digital transformation through a balanced integration of human-centered practices and technological innovations.

While the theoretical benefits of Quality 4.0 have been extensively discussed, empirical research remains limited. Most studies have focused on theoretical models or case studies, with fewer exploring how Quality 4.0 is operationalized across industries. Future research should investigate the practical implementation of Quality 4.0, focusing on the interaction between soft and hard dimensions and how these contribute to I4.0 readiness, adoption, and sustained performance (Ali et al., 2022).

Fundin et al. (2025) outlines key research themes for the future of Quality Management (QM) under the “Quality 2030” agenda, based on workshops with 42 researchers and practitioners in 2019. It identifies five core themes for QM research: (1) systems perspectives, (2) stability in change, (3) smart self-organizing models, (4) sustainable development integration, and (5) leveraging higher purpose in QM. The study also emphasizes preserving the core values of QM as the field evolves.

In conclusion, Quality 4.0 represents a significant evolution in quality management by combining traditional principles with cutting-edge Industry 4.0 technologies. It allows organizations to shift from reactive to proactive, data-driven systems that enhance quality, improve operational efficiency, and increase customer satisfaction. While challenges remain—especially for SMEs—Quality 4.0 holds great potential to drive digital transformation and organizational performance. Future research should continue exploring its operationalization, the dynamics between soft and hard dimensions, and its impact on Industry 4.0 adoption and long-term success.

2.3. Review of Kaizen 4.0

Kaizen, a philosophy rooted in continuous improvement and waste reduction, has evolved significantly with the rise of Industry 4.0 technologies. Historically focused on incremental, manual improvements, Kaizen now integrates advanced digital tools such as Artificial Intelligence (AI), the Internet of Things (IoT), Big Data, and automation. This transformation, referred to as Kaizen 4.0, represents a paradigm shift where digital technologies enhance Kaizen’s ability to drive smarter, faster, and scalable improvements, fostering greater productivity and sustainability in modern manufacturing and business environments (bin Wan Ibrahim et al., 2017; Gomaa, 2025c).

- Enhanced Functionality Through Digital Integration: A key feature of Kaizen 4.0 is the integration of cutting-edge digital technologies, enabling real-time, data-driven continuous improvement. IoT devices continuously monitor processes, generating vast amounts of data. This data is then analyzed through AI algorithms, facilitating predictive maintenance, optimizing performance, and reducing waste (Tripathi et al., 2022). Big Data analytics complements this by uncovering inefficiencies and providing insights that guide proactive decision-making. The use of digital twins—virtual models of physical assets—further strengthens Kaizen 4.0. By simulating processes before changes are implemented, digital twins help reduce risks and optimize improvements.

- Organizational and Cultural Implications: The success of Kaizen 4.0 hinges not only on technological adoption but also on leadership and organizational culture. While digital tools are essential for driving efficiency, their effectiveness is rooted in aligning them with Kaizen’s core values, including employee engagement, simplicity, and sustainable improvement (Ma et al., 2017; Sahmi & El Abbadi, 2024). Overcoming resistance to change and cultivating a culture of digital transformation requires strategic change management, ongoing training, and effective communication. Furthermore, implementing Kaizen 4.0 successfully requires collaboration between IT, operations, and management teams. Ensuring that digital tools are seamlessly integrated into Kaizen processes without disrupting workflows demands a coordinated effort to align technology with broader organizational goals.

- Frameworks and Maturity Models for Digital Integration: Several frameworks have been developed to guide organizations through the complexities of integrating digital technologies into Kaizen. The Kaizen 4.0 maturity model, proposed by Burggraf et al. (2020), offers a structured approach to adopting Industry 4.0 technologies, progressing from basic connectivity to fully autonomous systems. Similarly, Lean 4.0, which combines Lean principles with digital tools, has shown success in industries such as healthcare and logistics (Sanders et al., 2016; Ciano et al., 2021). These models provide practical pathways for businesses to scale continuous improvement initiatives, ensuring that digital tools complement traditional practices. Additionally, Gomaa’s (2025a,b) frameworks highlight how Lean Six Sigma, AI, Digital Twins, and predictive analytics can enhance Kaizen 4.0, Maintenance 4.0, and Supply Chain 4.0, offering a roadmap for real-time optimization, improved asset integrity, and operational resilience.

- Challenges in Kaizen 4.0 Adoption: The adoption of Kaizen 4.0 presents several challenges, many of which stem from resistance to change, digital illiteracy, and the complexity of integrating new technologies into established Kaizen practices (Goyal & Law, 2019; Santos et al., 2018). While the potential benefits are substantial, organizations must balance the sophistication of digital tools with Kaizen’s focus on small, incremental improvements. The influx of real-time data from IoT devices and advanced analytics can overwhelm traditional Kaizen methodologies. To address this, businesses need to develop standardized systems that integrate digital tools seamlessly into existing Kaizen processes. Moreover, scaling Kaizen 4.0 across large, diverse organizations—often with varying levels of digital maturity—requires tailored strategies to meet the specific needs of different departments or regions (Tripathi et al., 2022).

In conclusion, Kaizen 4.0 represents a significant advancement of traditional Kaizen principles, leveraging Industry 4.0 technologies to accelerate continuous improvement efforts. By integrating IoT, AI, Big Data, and automation, Kaizen 4.0 enables predictive maintenance, waste reduction, and real-time decision-making, aligning with Kaizen’s core objective of sustainable, incremental improvement. However, the successful implementation of Kaizen 4.0 extends beyond technology—it requires leadership, cultural transformation, and strategic alignment across the organization. As businesses continue to embrace digital transformation, overcoming the challenges associated with Kaizen 4.0 adoption will be essential for realizing its full potential. When effectively implemented, Kaizen 4.0 enhances operational efficiency, drives innovation, and supports long-term sustainability, making it a critical approach for organizations striving to remain competitive in the digital age.

2.4. Review of LSS 4.0

Lean Six Sigma (LSS) and Total Quality Management (TQM) are complementary methodologies designed to improve efficiency, reduce waste, and enhance product quality. TQM emphasizes continuous improvement through customer satisfaction and employee involvement, while Lean Six Sigma utilizes the data-driven DMAIC framework to eliminate waste and defects. Together, they optimize processes, aligning them more closely with customer needs, ensuring sustainable improvements (Gomaa 2024)

Lean Six Sigma 4.0 (LSS 4.0) builds on traditional Lean Six Sigma by integrating advanced Industry 4.0 technologies such as AI, IoT, Big Data, Digital Twins, and Cyber-Physical Systems. These technologies enable real-time monitoring, predictive analytics, and autonomous optimization, shifting decision-making from reactive to prescriptive. This results in improved operational efficiency, product quality, and resource utilization. However, challenges such as high initial costs, workforce adaptation, cybersecurity risks, and data interoperability need to be addressed. Future research should focus on refining LSS 4.0 frameworks, developing scalable integration strategies, and assessing its impact on sustainability, supply chain resilience, and workforce evolution (Gomaa 2025a-c).

Early studies (Sanders et al., 2016; Buer et al., 2018) indicated that Industry 4.0 technologies enhance Lean practices by driving automation and enabling data-driven decision-making. These studies also underscored the importance of structured implementation strategies to align digital technologies with Lean principles. Subsequent research (Tortorella et al., 2018; Ustundag et al., 2018) further emphasized the role of digital tools in optimizing Lean processes, particularly for equipment reliability and predictive maintenance.

Industry-specific studies have provided deeper insights into Lean 4.0’s applications. Tortorella et al. (2019) found that digitalization in Brazilian manufacturing introduces complexity, but product- and service-related digitalization enhances Lean outcomes. Varela et al. (2019) explored Lean 4.0’s sustainability benefits, demonstrating that Industry 4.0 contributes to economic, environmental, and social sustainability, though its direct impact on Lean practices requires further exploration. In healthcare, Ilangakoon et al. (2022) and Akanmu et al. (2022) showed efficiency gains from Lean 4.0 but highlighted challenges related to system integration and data security.

A central focus of ongoing research is the integration of digital technologies with Lean 4.0. Cifone et al. (2021) and Kumar et al. (2021) demonstrated how AI, Big Data, and IoT enhance decision-making and process optimization. Studies by Rosin et al. (2020) and Ciano et al. (2021) illustrated how automation strengthens Lean principles like Just-in-Time (JIT) and Jidoka, although they noted that digitalization alone does not guarantee waste reduction. Moreira et al. (2024) and Pongboonchai-Empl et al. (2024) explored how AI and Big Data optimize the DMAIC framework, improving defect prediction, root cause analysis, and process control.

Research by Bittencourt et al. (2021) and Santos et al. (2021) highlighted the importance of leadership commitment, workforce engagement, and a solid Lean foundation for successful digital transformation. Despite this, challenges like financial constraints and technical expertise limitations persist, especially for SMEs. Walas Mateo et al. (2023) proposed frameworks to address these barriers. In the area of maintenance, Komkowski et al. (2023) and Torre et al. (2023) underscored the role of TPM 4.0 in sustaining Lean-driven digital transformations by improving equipment reliability and reducing downtime.

Despite its advantages, Lean 4.0 also presents challenges that need further exploration. Johansson et al. (2024) and Galeazzo et al. (2024) identified tensions between IoT-driven decision-making and traditional Lean problem-solving, which prioritizes human expertise. Frank et al. (2024) examined conflicts between automation and Lean principles, suggesting that excessive digitalization could undermine Lean’s human-centered approach. Additionally, Hines et al. (2023) and Kassem et al. (2024) pointed to challenges in standardization and interoperability, stressing the need for robust frameworks that ensure the seamless integration of digital technologies.

Future research should continue to refine integration frameworks, address the challenges of digital transformation, and evaluate the impact of LSS 4.0 on sustainability, supply chain resilience, and workforce transformation. Striking the right balance between automation and Lean’s human-centered principles will be crucial for the long-term success of Lean 4.0 across industries. Future studies should continue to explore theoretical foundations, digital technology integration, and the role of LSS 4.0 in maintenance, manufacturing, healthcare, and sustainability.

Finally, emerging strategies, as presented by Gomaa (2025a,b), introduce frameworks combining Lean Six Sigma, AI, Digital Twins, and predictive analytics within Lean 4.0, Maintenance 4.0, and Supply Chain 4.0. These models facilitate real-time optimization, improve asset integrity, and enhance operational resilience across manufacturing ecosystems.

In conclusion, this review provides a thorough examination of LSS 4.0’s evolution, its integration with Industry 4.0, and emerging trends in smart and sustainable manufacturing. It highlights the importance of interdisciplinary research and strategic approaches to fully harness the potential of LSS 4.0 across industries.

3. Research Gap Analysis for Quality 4.0

Quality Management (QM) has long been recognized as an effective methodology for enhancing organizational efficiency, reducing waste, improving product quality, and ensuring customer satisfaction. With the rise of Industry 4.0 technologies—such as Artificial Intelligence (AI), the Internet of Things (IoT), Big Data, Digital Twins, and Cyber-Physical Systems—the approach to quality management is rapidly evolving. This shift has given rise to Quality 4.0, which integrates traditional TQM principles with advanced technological solutions to optimize processes, enhance quality, and enable real-time decision-making. Despite its potential, several research gaps remain in understanding how to effectively integrate these technologies within the QM framework. Table 2 presents key research gaps and future directions for advancing Quality 4.0, with a focus on integrating Industry 4.0 technologies. The following is a refined summary of the primary research areas:

- Human Factors & Workforce: Existing research often overlooks the involvement of the workforce in adopting Quality 4.0. Future research should explore strategies for employee training, engagement, and the development of skills necessary to leverage digital technologies effectively.

- Lean Practices Integration: There is limited research on integrating Lean principles with Quality 4.0. Future studies should focus on developing frameworks that combine Lean and Quality 4.0 to enhance operational efficiency and continuous improvement.

- Change Management: Implementing Quality 4.0 involves significant organizational changes. Research should investigate effective change management strategies that ease the transition to digital and data-driven processes.

- Real-Time Decision-Making & Automation: While real-time decision-making and automation are critical to Quality 4.0, they remain underexplored. Future research should focus on the integration of AI, IoT, and real-time analytics to improve process optimization and decision-making.

- Standardization: The lack of standardized frameworks for Quality 4.0 adoption remains a significant gap. Research should aim to develop universal frameworks that guide consistent implementation across industries.

- Cross-Industry Applications: Quality 4.0’s applicability across different sectors has not been sufficiently explored. Research should adapt Quality 4.0 to the specific needs of various industries and develop sector-specific best practices.

- AI, IoT, Big Data Integration: Research on integrating AI, IoT, and Big Data into Quality 4.0 is still developing. Future studies should explore how these technologies can enhance quality control, operational efficiency, and decision-making processes.

- Sustainability: The role of Quality 4.0 in advancing sustainability goals has not been fully investigated. Research should focus on how Quality 4.0 can optimize processes to achieve economic, environmental, and social sustainability.

- Supply Chain Integration: The impact of Quality 4.0 on supply chain management remains underexplored. Future research should focus on how Quality 4.0 can enhance supply chain resilience and optimize operations.

- Predictive Analytics: Predictive analytics for quality improvement within Quality 4.0 is still in its infancy. Future research should develop models that predict and address quality issues early, enhancing proactive management.

- Cybersecurity: As digital technologies are increasingly integrated into Quality 4.0, cybersecurity risks become more critical. Research should focus on safeguarding Quality 4.0 systems, ensuring data privacy, and protecting sensitive information.

- Customer-Centricity: There is a gap in understanding how Quality 4.0 can enhance customer satisfaction through digital technologies. Future research should explore how Quality 4.0 can improve customer experience and engagement using data-driven insights.

- Data Interoperability: Data interoperability challenges hinder the seamless implementation of Quality 4.0. Future research should focus on solutions that ensure smooth data integration across disparate systems, enhancing collaboration and information flow.

- Performance Metrics: Existing metrics for assessing the effectiveness of Quality 4.0 are insufficient. Future research should focus on developing new performance metrics that assess the impact of Quality 4.0 on organizational performance, ensuring continuous improvement.

In conclusion, Quality 4.0 represents a transformative evolution in quality management, combining traditional principles with the advanced capabilities of Industry 4.0 technologies. However, to fully unlock its potential, it is essential to address the existing research gaps, particularly in the integration of digital technologies, workforce management, data interoperability, and performance measurement. By addressing these gaps, researchers can provide the necessary frameworks and insights to guide organizations through the digital transformation and ensure the successful implementation of TQM

Table 2. Key Research Gaps & Future Research Directions for Quality 4.0.

| Research Area | Gaps | Future Research Directions | |

|---|---|---|---|

| 1 | Human Factors & Workforce | Insufficient focus on workforce skills and engagement. | Investigate strategies for employee training, engagement, and role transformation. |

| 2 | Lean Practices Integration | Limited integration research between Lean and Quality 4.0. | Develop frameworks to merge Lean principles with Quality 4.0 in various industries. |

| 3 | Change Management | Lack of focus on managing change during adoption. | Explore methods to overcome resistance and facilitate organizational transformation. |

| 4 | Real-Time Decision-Making & Automation | Insufficient exploration of real-time decision-making. | Research AI, IoT, and real-time analytics for enhanced process optimization. |

| 5 | Standardization | Absence of standardized frameworks for Quality 4.0 adoption. | Create universal frameworks for consistent Quality 4.0 implementation. |

| 6 | Cross-Industry Applications | Limited cross-industry research. | Conduct cross-sector studies to understand best practices for Quality 4.0 adoption. |

| 7 | AI, IoT, Big Data Integration | Underexplored integration of digital technologies. | Investigate AI, IoT, and Big Data for quality control and operational efficiency. |

| 8 | Sustainability | Limited research on sustainability in Quality 4.0. | Explore the role of Quality 4.0 in promoting sustainability in business practices. |

| 9 | Supply Chain Integration | Lack of focus on Quality 4.0’s role in supply chain management. | Research the impact of Quality 4.0 on supply chain optimization and resilience. |

| 10 | Predictive Analytics | Limited use of predictive analytics in quality improvement. | Develop predictive models to prevent quality issues and improve processes. |

| 11 | Cybersecurity | Unexplored cybersecurity risks in Quality 4.0. | Research strategies for securing Quality 4.0 systems and data from cyber threats. |

| 12 | Customer-Centricity | Insufficient focus on customer-oriented strategies. | Explore how Quality 4.0 technologies can enhance customer satisfaction and engagement. |

| 13 | Data Interoperability | Challenges in seamless data interoperability. | Investigate solutions for improved data sharing and system integration. |

| 14 | Performance Metrics | Lack of comprehensive performance metrics for Quality 4.0. | Develop new metrics to assess the effectiveness and impact of Quality 4.0. |

4. Research Methodology for Quality 4.0 Implementation

This section outlines the methodology for implementing Quality Management 4.0 (Quality 4.0), integrating traditional quality management principles with Industry 4.0 technologies to improve operational efficiency, product quality, and sustainability in the digital age.

- Core Principles of Quality 4.0: Quality 4.0 combines traditional principles with Industry 4.0 technologies, focusing on continuous improvement, customer satisfaction, and agility. This synergy helps organizations achieve operational excellence while staying adaptable to technological advancements.

- Role of Industry 4.0 Technologies: Technologies like IoT, AI, big data, and automation are central to Quality 4.0, enabling real-time monitoring, predictive maintenance, and data-driven decisions. These tools enhance quality management, reduce risks, and improve operational efficiency.

- Quality 4.0 Implementation Framework: A structured framework is essential for successful Quality 4.0 implementation. It aligns traditional quality management practices with Industry 4.0 tools, ensuring seamless integration of digital solutions to optimize processes and deliver sustainable improvements.

- DMAIC Methodology in Quality 4.0: The DMAIC (Define, Measure, Analyze, Improve, Control) methodology underpins Quality 4.0’s approach to continuous improvement. It helps organizations identify issues, measure performance, analyze causes, and implement data-driven solutions to drive long-term quality improvements.

- Strategic Objectives and KPIs: Clear strategic objectives and KPIs are key to assessing the effectiveness of Quality 4.0. Goals such as improving quality, reducing costs, and enhancing customer satisfaction should be tracked with KPIs to ensure progress and success.

- Challenges and Considerations: Key challenges in Quality 4.0 implementation include technological integration, workforce adaptation, and data privacy concerns. These can be mitigated through careful planning, stakeholder engagement, and targeted training to ensure a smooth transition.

In conclusion, Quality 4.0 blends traditional quality management principles with Industry 4.0 technologies, enabling organizations to improve efficiency, quality, and sustainability. By adopting Quality 4.0, businesses can enhance their competitiveness, make informed decisions, and secure long-term success in the digital era.

4.1. Core Principles of Quality 4.0 for Achieving Operational Excellence

Quality 4.0 marks the transformation of traditional Total Quality Management by seamlessly integrating advanced Industry 4.0 technologies—such as Artificial Intelligence (AI), the Internet of Things (IoT), Big Data, Robotic Process Automation (RPA), and cloud computing—into core quality practices. This integration empowers organizations with real-time insights, predictive capabilities, and data-driven decision-making, enabling proactive quality management and agile responses to operational challenges. By embedding digital technologies into the foundational principles of TQM, businesses can drive continuous improvement, enhance customer satisfaction, and build resilient, adaptive systems. Ultimately, Quality 4.0 serves as a strategic enabler of operational excellence, supporting efficiency, sustainability, and competitive advantage in an increasingly dynamic and technology-driven landscape.

Table 3 outlines the core principles guiding organizations toward operational excellence, agility, and sustainability in a digital-first world.

- Customer-Centric Quality: Quality 4.0 prioritizes customer satisfaction by using AI and predictive analytics to anticipate customer needs. This enables businesses to offer personalized solutions and proactively resolve issues, building stronger customer loyalty and aligning quality with customer value.

- Data-Driven Decision Making: This principle focuses on leveraging big data and predictive analytics to make informed decisions. By analyzing data trends, organizations can improve operational efficiency, prevent quality issues before they arise, and base decisions on evidence rather than intuition.

- Continuous Improvement through Automation: Automation, powered by AI, machine learning, and robotic process automation (RPA), is central to continuous quality improvement. By reducing human error and optimizing processes, businesses can ensure consistent quality, while real-time monitoring allows for quick identification and resolution of issues.

- Smart Workforce Empowerment: Quality 4.0 empowers employees with real-time data, AI-driven tools, and digital training to make effective decisions. This enhances innovation, collaboration, and responsiveness, enabling a workforce that drives continuous improvement in quality and productivity.

- Integrated Digital Quality Systems: Quality 4.0 integrates quality management systems across the organization using cloud platforms, ERP, and IoT. This ensures real-time data flow and seamless communication, aligning quality standards throughout the value chain and improving operational efficiency.

- Collaborative & Transparent Supply Chain: Through technologies like blockchain and IoT, Quality 4.0 ensures transparency and collaboration in the supply chain. Real-time monitoring and traceability of products from raw materials to finished goods help maintain quality and strengthen supplier relationships.

- Leadership in Digital & Quality Transformation: Effective leadership is crucial for guiding digital transformation and ensuring quality excellence. Data-driven leadership, supported by real-time analytics and digital strategies, fosters a culture of innovation, empowering employees to continuously improve quality and performance.

- Sustainability and Ethical Quality: Quality 4.0 incorporates sustainability and ethical practices into quality management. By using technologies to track environmental impact, optimize resource usage, and ensure ethical sourcing, businesses can deliver eco-friendly products while improving quality and enhancing their brand reputation.

- Proactive Risk Management: This principle emphasizes the proactive identification and management of risks. Using IoT and AI-powered predictive maintenance, businesses can monitor asset health and prevent failures before they disrupt operations, minimizing downtime and maintaining quality standards.

- Agility and Flexibility: Agility is critical in a rapidly changing market. Quality 4.0 supports flexible systems and agile methodologies, enabling organizations to quickly adjust their quality management processes to meet evolving customer demands and market conditions while maintaining high standards.

- Predictive Maintenance: By utilizing IoT sensors and AI, predictive maintenance anticipates equipment failures before they occur, reducing downtime and ensuring that assets remain in optimal condition. This helps maintain continuous product quality and operational efficiency.

In conclusion, Quality 4.0 merges traditional quality management with Industry 4.0 technologies like AI, IoT, blockchain, and big data. This integration enables businesses to enhance customer satisfaction, streamline operations, and drive continuous improvement. By focusing on data-driven decisions, automation, sustainability, and an empowered workforce, organizations can maintain high-quality standards in an increasingly digital world.

Table 3. Core Principles of Quality 4.0 for Achieving Operational Excellence.

| Core Principle | Objective | Description | Key Focus Areas |

|---|---|---|---|

| Customer-Centric Quality | Anticipate and meet customer needs using technology. | Leverages AI, predictive analytics, and big data to personalize experiences and resolve issues proactively. | - AI & Predictive Analytics - Personalized Solutions - Proactive Issue Resolution |

| Data-Driven Decision Making | Make informed decisions based on data. | Uses big data and AI to drive evidence-based decisions and improve quality. | - Big Data Analytics - Predictive Insights - Evidence-Based Decisions |

| Continuous Improvement through Automation | Enhance processes and reduce errors via automation. | Integrates AI, machine learning, and RPA to automate tasks and maintain consistent quality. | - AI & Machine Learning - Robotic Process Automation (RPA) - Real-Time Monitoring |

| Smart Workforce Empowerment | Equip employees with digital tools to drive innovation. | Provides real-time dashboards and AI tools to empower employees in making impactful quality decisions. | - AI Tools - Real-Time Dashboards - Digital Training |

| Integrated Digital Quality Systems | Unify quality management across the organization. | Uses cloud platforms, ERP, and IoT to integrate data, enabling seamless quality management. | - Cloud-Based Systems - ERP & IoT Integration - Real-Time Data Flow |

| Collaborative & Transparent Supply Chain | Enhance supply chain quality through collaboration and transparency. | Blockchain and IoT ensure traceability and real-time monitoring across the supply chain. | - Blockchain - IoT Monitoring - Supplier Collaboration |

| Leadership in Digital & Quality Transformation | Integrate digital technologies with quality goals. | Leaders use data-driven strategies to foster a culture of continuous quality improvement and innovation. | - Data-Driven Leadership - Digital Strategy - Quality Innovation |

| Sustainability and Ethical Quality | Integrate sustainability and ethical practices in quality management. | Focuses on sustainable practices and ethical sourcing, enhancing long-term brand value. | - Sustainable Practices - Ethical Sourcing - Environmental Impact Monitoring |

| Proactive Risk Management | Prevent risks through predictive technology. | Uses IoT sensors, AI, and machine learning to predict and prevent disruptions in operations. | - Predictive Maintenance (IoT) - AI-Driven Risk Forecasting - Downtime Minimization |

| Agility and Flexibility | Adapt quickly to changing market conditions. | Agile methodologies and flexible systems allow rapid adjustments to market shifts and customer needs. | - Agile Methodologies - Flexible Systems - Real-Time Adjustments |

| Predictive Maintenance | Minimize downtime through predictive maintenance. | Leverages IoT and AI to monitor equipment health and schedule preventive maintenance. | - IoT Sensors - AI & Machine Learning - Preventive Maintenance Scheduling - Real-Time Monitoring |

4.2. Industry 4.0 Technologies for Enhanced Operational Excellence

Industry 4.0 technologies are revolutionizing operational processes by driving efficiency, quality, and sustainability across industries. Innovations such as IoT, AI, automation, big data, blockchain, and workforce transformation empower organizations to optimize operations, enhance decision-making, and improve product outcomes. Table 4 outlines the key technologies, their impact on operational excellence, and the strategic advantages they provide, supported by real-world examples from leading companies like Tesla, Amazon, and Walmart.

- IoT and Smart Sensors: IoT devices and smart sensors provide real-time data, enabling continuous monitoring of equipment and production lines. This allows businesses to implement predictive maintenance, preventing issues before they cause downtime. Additionally, IoT improves resource utilization and reduces energy consumption, leading to cost savings and increased sustainability. By enabling autonomous decision-making, IoT enhances efficiency and responsiveness. For example, GE uses IoT for maintenance predictions, while Tesla integrates IoT to improve production efficiency.

- AI and Machine Learning: AI and Machine Learning (ML) help businesses analyze large datasets to predict problems and improve decision-making. AI automates routine tasks, reducing human error and improving product quality, while ML continuously optimizes processes in real time. This enables companies to be more agile and make faster, data-driven decisions. Siemens applies AI for predictive maintenance, and Netflix uses machine learning to personalize content recommendations.

- Automation and Robotics: Automation and robotics streamline repetitive tasks, reducing human error and increasing production speed and quality. Robots ensure consistency, allowing businesses to maintain high standards while reducing labor costs. The flexibility of robotics allows for scalable production to meet demand. ABB utilizes collaborative robots (cobots) to enhance productivity, and Tesla incorporates robotics to reduce assembly time and costs.

- Big Data and Analytics: Big Data and analytics empower businesses to make data-driven decisions by uncovering insights in large datasets. These technologies help companies forecast demand, optimize resource allocation, and improve inventory management, leading to enhanced operational performance. Real-time analytics foster continuous improvement. For example, Amazon uses Big Data to optimize its supply chain, and Walmart utilizes analytics to ensure product availability.

- Blockchain: Blockchain ensures security, transparency, and traceability by recording transactions on an immutable ledger. Using smart contracts, blockchain automates agreements and enhances trust across stakeholders. This results in more efficient and secure supply chains. Walmart uses blockchain for food traceability, while Maersk employs blockchain to streamline shipping and logistics processes.

- Integration and Interoperability: Integration and interoperability allow various systems to seamlessly share data, improving collaboration and real-time decision-making across departments. Cloud platforms, AI, and digital twins enhance these integrations, ensuring that data from different systems is unified for efficient analysis. This leads to greater operational efficiency. Bosch uses cloud-based systems for integration, while Siemens integrates physical and digital systems with digital twins to optimize performance.

- Workforce Transformation: Workforce transformation focuses on upskilling employees to work alongside AI, automation, and robotics. This ensures a future-ready workforce that can drive innovation and focus on higher-value tasks, while machines handle repetitive work. For example, ABB trains employees in robotics and AI, while Google provides digital upskilling programs to equip employees with the skills needed in the age of AI and machine learning.

In summary, Industry 4.0 technologies such as IoT, AI, automation, big data, blockchain, and workforce transformation are enhancing operational excellence by improving efficiency, product quality, and sustainability. These innovations enable businesses to be more agile, make data-driven decisions, and foster better collaboration, ultimately driving long-term success and competitive advantage. Companies like Tesla, Amazon, and Walmart showcase how these technologies lead to operational improvements and enhanced market performance.

Table 4. Industry 4.0 Technologies for Enhanced Operational Excellence.

| Technology | Impact on Operational Excellence | Strategic Benefits | Industry Examples |

|---|---|---|---|

| IoT & Smart Sensors | - Provides real-time data for predictive maintenance and asset management.- Optimizes resource and energy usage. | - Supports autonomous decision-making.- Enhances operational efficiency with continuous data feedback. | GE: Predictive maintenance using IoT.Tesla: Real-time factory monitoring. |

| AI & Machine Learning | - Generates predictive insights and automates processes.- Reduces errors and improves product quality.- Personalizes customer experiences. | - Drives dynamic optimization.- Fosters faster innovation and market responsiveness. | Siemens: AI for predictive maintenance.Netflix: AI-powered content recommendations. |

| Automation & Robotics | - Increases precision, consistency, and speed.- Reduces human error and labor costs.- Enables mass customization. | - Enhances flexible manufacturing.- Improves productivity with collaborative robots. | ABB: Collaborative robots (cobots) for human-robot teamwork.Tesla: Robotics for assembly line automation. |

| Big Data & Analytics | - Improves decision-making with real-time data.- Enhances demand forecasting and resource optimization. | - Unlocks predictive insights.- Enables data-driven operational strategies. | Amazon: Data-driven supply chain optimization.Walmart: Big data for inventory and demand management. |

| Blockchain | - Enhances supply chain transparency and security.- Automates processes with smart contracts.- Ensures data traceability. | - Builds trust and accountability.- Enables secure, decentralized transactions. | Walmart: Blockchain for food traceability.Maersk: Blockchain securing logistics. |

| Integration & Interoperability | - Connects systems for seamless operations.- Enhances collaboration and cloud-based data sharing. | - Powers AI-driven ecosystems.- Ensures real-time integration for faster decision-making. | Bosch: Cloud-based system integration.Siemens: Digital twins for operational integration. |

| Workforce Transformation | - Upskills employees for digital roles.- Encourages human-machine collaboration.- Shifts focus to strategic tasks. | - Promotes continuous learning.- Fosters innovation and high-value creativity. | ABB: Robotics and AI workforce training.Google: Digital skill development for AI and machine learning. |

4.3. Quality 4.0 Implementation Framework

This Framework is designed to help organizations navigate the integration of Total Quality Management (TQM) into the digital era. With the rapid advancements in Industry 4.0 technologies, organizations must evolve their quality management systems to harness data-driven insights, automation, and sustainability. Table 5 outlines the strategic areas, key objectives, actionable steps, and expected outcomes to guide organizations in implementing Quality 4.0 effectively.

- Leadership & Agility: This area focuses on empowering leadership to drive agile, data-driven transformations. Actions include forming a leadership council to guide digital transformation, adopting agile methodologies, and equipping leaders with training on digital tools. The expected outcomes are faster decision-making, stronger leadership commitment to Quality 4.0, and a well-prepared leadership team that can drive the transformation.

- Customer-Centric Quality: Prioritizing customer satisfaction, this area emphasizes personalized quality offerings. Key steps include integrating AI-powered CRM systems, utilizing big data for tailored experiences, and enabling customer co-creation platforms. These efforts will enhance customer loyalty, provide real-time insights into satisfaction, and foster continuous innovation.

- Data-Driven Decision Making: This strategic area aims to enable faster and more informed decisions using data analytics and AI. Key actions include centralizing data, integrating AI for decision support, and deploying autonomous quality control systems. Expected outcomes include quicker, more accurate decisions, reduced manual checks, and ongoing improvements in quality.

- Automation & Lean Optimization: Focused on optimizing operational efficiency, this area integrates automation with Lean Six Sigma. Key initiatives include automating repetitive tasks, leveraging IoT for smart manufacturing, and combining Lean Six Sigma with AI and IoT. This will result in improved operational efficiency, reduced defects, and optimized processes.

- Predictive Risk Management: This area leverages predictive tools to proactively manage risks. Core actions involve deploying IoT sensors for predictive maintenance, developing digital twins for risk simulation, and implementing risk-based inspections. These measures will help minimize downtime, improve risk identification, and optimize asset management.

- Supply Chain & Supplier Quality: Ensuring quality across the entire supply chain, this area emphasizes transparency and collaboration. Key initiatives include using blockchain for supply chain transparency, collaborating with suppliers through digital platforms, and automating supplier evaluations. This will lead to better supplier collaboration, fewer disruptions, and enhanced quality compliance.

- Employee Engagement & Digital Skills: This area empowers employees by integrating digital tools and fostering continuous learning. Steps include launching upskilling programs, gamifying quality initiatives, and creating cross-functional teams. Expected outcomes include a skilled, engaged workforce aligned with quality goals, driving innovation and contributing to continuous improvement.

- Sustainable Quality & Innovation: This area aligns Quality 4.0 with sustainability practices, integrating environmental and social responsibility into quality management. Actions include incorporating sustainability metrics, adopting circular economy principles, and using AI to predict environmental impacts. The outcomes are a reduced environmental footprint, innovation fueled by sustainability, and an enhanced corporate reputation.

In conclusion, focusing on these eight strategic areas will enable organizations to successfully implement Quality 4.0, driving operational excellence, customer satisfaction, employee engagement, and long-term sustainability.

Table 5. Quality 4.0 Implementation Framework.

| Strategic Area | Objective | Key Steps | Expected Outcomes |

|---|---|---|---|

| Leadership & Agility | Embed Quality 4.0 through agile, data-driven leadership. | - Form Leadership Council. - Implement agile methods. - Provide leadership training on digital tools. | - Enhanced decision-making agility. - Strong leadership commitment. - Skilled leadership team. |

| Customer-Centric Quality | Surpass customer expectations with personalized quality. | - Integrate AI-powered CRM. - Leverage Big Data for personalization. - Develop co-creation platforms. | - Increased customer loyalty. - Real-time satisfaction insights. - Enhanced innovation. |

| Data-Driven Decision Making | Enable faster, informed decisions through AI and analytics. | - Centralize data. - Implement AI decision support. - Introduce autonomous quality control systems. | - Accelerated decision-making. - Fewer manual quality checks. - Continuous improvement. |

| Automation & Lean Optimization | Optimize operations through automation and Lean Six Sigma. | - Automate repetitive tasks with RPA. - Implement smart manufacturing. - Integrate Lean Six Sigma with AI/IoT. | - Increased operational efficiency. - Reduced defects. - Streamlined processes. |

| Predictive Risk Management | Proactively mitigate risks using predictive tools. | - Deploy IoT for predictive maintenance. - Create digital twins for risk simulations. - Implement Risk-Based Inspections (RBI). | - Reduced downtime. - Timely risk identification. - More efficient asset management. |

| Supply Chain & Supplier Quality | Ensure quality consistency and visibility across the supply chain. | - Implement blockchain for transparency. - Collaborate with suppliers using digital platforms. - Automate supplier performance evaluations. | - Improved supplier collaboration. - Fewer disruptions. - Enhanced quality compliance. |

| Employee Engagement & Digital Skills | Empower employees with digital tools and continuous learning. | - Launch upskilling and reskilling programs. - Gamify quality improvement initiatives. - Create cross-functional innovation teams. | - Skilled, innovative workforce. - Higher employee participation. - Strong alignment with quality goals. |

| Sustainable Quality & Innovation | Align Quality 4.0 with sustainability for long-term impact. | - Integrate sustainability metrics. - Adopt circular economy principles. - Use AI to predict environmental impact. | - Lower environmental footprint. - Innovation driven by sustainability. - Enhanced corporate reputation. |

4.4. Enhanced DMAIC Methodology in Quality 4.0

The DMAIC methodology within Quality 4.0 provides a structured, data-driven approach to continuous improvement. Each phase—Define, Measure, Analyze, Improve, and Control—leverages advanced technologies to support decision-making and ensure sustainable improvements. By integrating AI, IoT, and machine learning, organizations can streamline processes, enhance efficiency, and foster innovation, ultimately leading to better customer satisfaction and business performance. Table 6 outlines the DMAIC framework, a core methodology in Total Quality Management (TQM), driving process improvements. This approach provides a systematic path to problem-solving and continuous enhancement, aligning each phase with strategic objectives, key actions, enabling technologies, and measurable outcomes.

- In the Define phase, the focus is on aligning quality goals with business strategy and customer needs. This involves clearly defining the project scope, setting goals that reflect organizational priorities, and engaging key stakeholders to ensure alignment. Customer-centered metrics are also established to guide the improvement process. Technologies like AI-driven insights, digital dashboards, and cloud platforms enhance data collection and collaboration. The result is a well-defined project scope, strong stakeholder alignment, and clear customer-focused metrics.

- The Measure phase centers on capturing real-time data and establishing performance baselines. The first step is identifying key performance metrics, followed by collecting baseline data to understand current performance. Continuous monitoring is then implemented to track metrics and detect potential issues early. Technologies such as IoT sensors, big data analytics, and cloud storage ensure data accuracy and accessibility. The outcomes include reliable baselines, real-time tracking, and proactive issue detection.

- In the Analyze phase, the goal is to identify root causes of inefficiencies or issues in processes. Data collected in the Measure phase is analyzed to uncover trends and patterns. Advanced analytics tools, including machine learning and process mining, help identify the root causes of problems. Integrating ERP-CRM systems provides deeper process insights, enabling data-driven decisions. This phase results in the identification of root causes, optimized processes, and better decision-making.

- The Improve phase focuses on implementing process enhancements through agile methodologies and technological solutions. Improvement opportunities are identified, solutions are tested, and changes are implemented iteratively to allow for rapid feedback and refinement. AI-driven quality control, simulation tools, and IoT automation are leveraged to optimize workflows and improve performance. This phase leads to streamlined processes, continuous innovation, and swift implementation of improvements.

- The Control phase ensures that improvements are maintained over time through continuous monitoring and feedback. Automated monitoring tools track performance, while KPIs (Key Performance Indicators) are defined to measure success. Feedback loops are implemented to ensure ongoing improvement. Technologies like AI monitoring, blockchain, and real-time KPIs provide transparency, enabling proactive issue resolution. This phase results in stable, efficient processes and early detection of problems, ensuring continuous improvement.

In conclusion, the DMAIC framework within Quality 4.0 offers a systematic, data-driven approach to quality management and continuous improvement. Integrating technologies such as AI, IoT, and machine learning in each phase—Define, Measure, Analyze, Improve, and Control—ensures that performance improvements are not only achieved but also sustained. This comprehensive approach leads to optimized processes, greater customer satisfaction, and long-term business success.

Table 6. Enhanced DMAIC Methodology in Quality 4.0.

| Phase | Strategic Focus | Key Steps | Technologies | Key Outcomes |

|---|---|---|---|---|